1

1

1, the composition of exhaust gas:

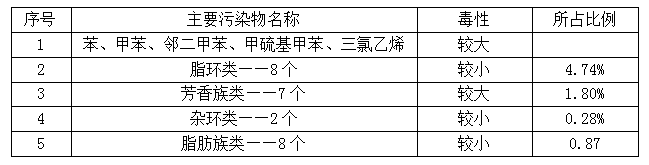

As the rubber in the production process will produce a lot of flue gas, rubber exhaust gas odor composition complex. Alkanes, alkynes, aromatic hydrocarbons; alcohols, phenols, aldehydes, ketones, organic acids and so on. The inorganic substances are H2S, SO2, carbon black, etc., the vast majority of malodorous gases produced by the original material for the organic material. These substances on human health hazards. The chemical composition of the domestic has not been reported, according to EPA / NIH provided data, there are 26 major pollutants, of which the following are several

表2-1:主要污染物表

2, the nature of exhaust:

The main components of the exhaust gas are, mainly tar, benzene, toluene, xylene, sulfur dioxide, hydrogen sulfide, nitrogen oxides, non-methane total hydrocarbons, ethyl acetate and chlorobenzene (some brand adhesives) and other toxic and harmful gas.

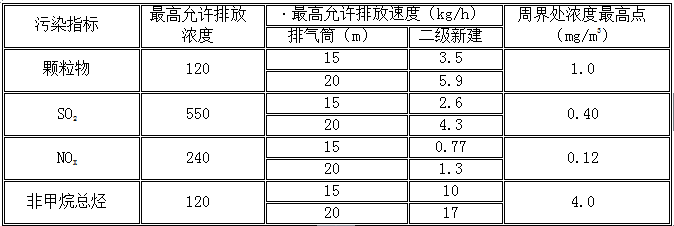

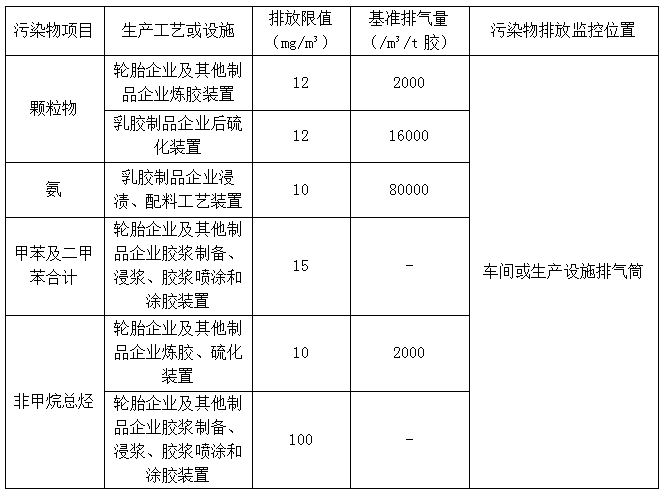

In order to protect people's health, the state has developed a rubber production of emission control standards (mg / m3):

The main ones are: benzene and toluene <4 0, xylene <1 0 0, tar and gasoline <350.

In addition, many of the ingredients with lead, chromium, nickel, arsenic and other heavy metals, and toxicity is not yet fully clear mixing, vulcanization, plastics, such as flue gas, have different degrees of poisoning the human body.

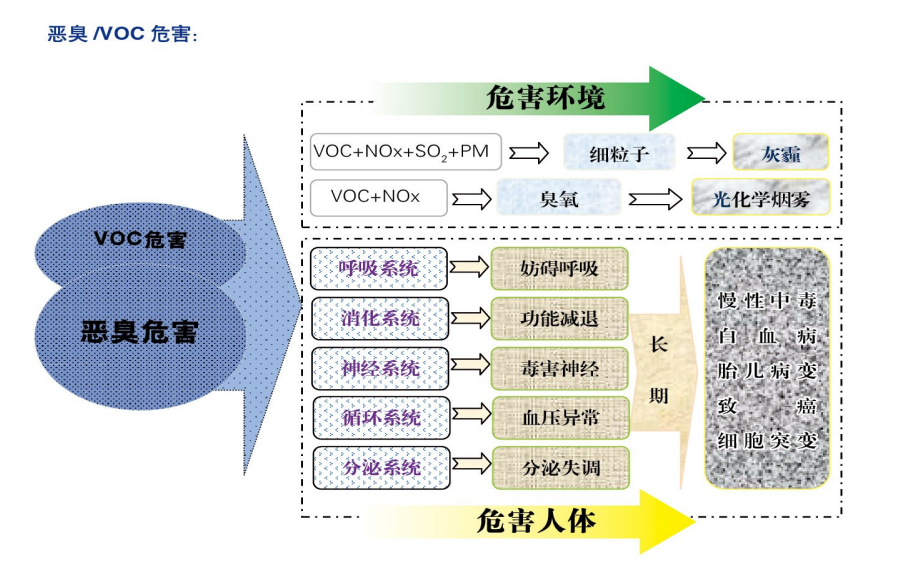

3, the stench of harmful substances on the human body:

Volatile organic odor gas is harmful to human health, often accompanied by odor, odor is distributed in the air, the factory workers eye, nose, respiratory irritation, heart, lung, liver and other organs and the nervous system harmful Impact, or even cause acute and chronic poisoning, can be carcinogenic, mutagenic. Such as benzene, toluene, xylene smell gas, because of its toxicity, long-term exposure to the skin through inhalation or absorbed into the body, will cause liver damage, hematopoietic organs and nervous system damage, late can develop into aplastic anemia , And even into leukemia.

4, odor treatment difficulty:

According to Weber-Fecher's law, when the concentration of air pollutants is proportional to the change, the degree of harm to the human body and the ecological environment into the same degree of change, the stench to the people (Odor intensity) is proportional to the logarithm of the stench amount of the stench substance to the human olfactory sensation. When the malodor concentration is reduced by 97% and the odor intensity is reduced by only 50%, that is, the odorant is removed by only 3% But it seems to reduce the half, a very small amount of odor substances can give a strong sense of stench.

By the comparison table, such as dimethyl disulfide, the smell of people feel the odor concentration decreased by 3 units (from 5 to 2), the need to remove the ratio is (1-0.0026 / 7.902) × 100% = 99.967%.

(1-0.5267 / 7.902) × 100% = 93.33% Therefore, the treatment of stench is a very challenging task.

If from 5 to a level, you need to remove (1-0.0003 / 7.902) × 100% = 99.996%, which is very difficult to achieve.

Odor index:

Definition: N = 10 × lg (X) (Ouda)

Where: N-odor index.

X-odor concentration

Japan provides that, as long as the odor strength to 3, it belongs to the scope of governance must be.

5, malodorous gas pollution diagram:

6, malodor treatment technology status and choice

For high concentrations of malodorous gases, the industry deodorant technology mainly in the following categories, there are some defects.

Masking method through another type of odor substances and odor mixed to cover the smell of the method, can be temporary deodorant effect. But the technology does not really remove the odor, but the way to deceive the smell, while the aroma will increase the VOC content; adsorption adsorption of odor through the adsorbate (such as activated carbon), but the adsorbate is easy to saturation failure, Biological method can not guarantee the long-term stability of microbial survival; UV photolysis technology in this industry, the use of equipment required for the volume too much, too many tubes, and because of the use of light tubes The short life of the reasons leading to a high input and operating costs; plasma method requires odor and direct contact with the discharge medium, resulting in the discharge medium is easy to corrosion or poisoning failure, such equipment is not suitable for the industry structure.

7, the choice of treatment process:

Because the content of rubber exhaust gas is more complex, the concentration of odor is high, the single process can not achieve the purpose of deodorizing the exhaust gas. To make the treated waste gas meet the national standard of stench gas emission, the process must be combined together deal with. Therefore, under the premise of full consideration of the physical and chemical properties of pollutants and treatment effects, combined with an investment and operating costs, the program uses cost-effective composite catalytic oxidation technology for purification treatment.

Composite catalytic oxidation process principle: the use of the corresponding catalytic oxidant to the chemical degradation of harmful gases, mixed contact reaction, and then with the oxidant collision, so that it into harmless substances, and finally through the demister fog discharge standards. The exhaust gas is firstly collected by the absorption port and adjusted to the optimal flow rate by the flow regulating valve. The adjusted exhaust gas is collected by the branch pipe from the branch pipe to the supervisor and then enters into the exhaust gas purification unit for catalytic oxidation and is highly oxidized under the action of a catalyst. The reaction principle is at room temperature and pressure, and the oxidant electron coupling, resulting in a more stable hydroxyl radicals or peroxide radicals. These free radicals have very strong oxidizing properties and can react with the organic compounds in the exhaust gas. The organic radicals generated by the reaction can continue to participate in the chain reaction. Will not be absorbed by the chemical absorption of organic gases in the exhaust gas decomposition of unsaturated hydrocarbons, so that hydrocarbons in the unsaturated hydrocarbons quickly oxidized into H2O and CO2, so as to achieve the purpose of the exhaust gas purification. This process runs low cost, no clogging, long-term stable operation, safe and reliable.

8, the process

The waste gas produced in the vulcanization process of the rubber products is sent to the exhaust gas purification unit after being exhausted into the exhaust gas purification unit, and the exhaust gas is purified and purified in the exhaust gas purification unit. First, the particulate matter in the exhaust gas is exhausted, and the harmful components in the absorption liquid and exhaust gas are collided fully. After reaction and purification, remove the harmful substances, and then into the oxidation device, the decomposition of the integrated odor components in the exhaust, and then by the mist eliminator, and finally through the exhaust fan exhaust.

The internal structure of the exhaust gas purification unit adopts a special structure, and a multi-layer swirling device is built in, and the absorbing liquid and the exhaust gas are fully contacted and decomposed by the catalytic oxidant to remove the material which can not be absorbed.

Waste gas collection and treatment process block diagram is as follows:

![]()

9, processing requirements:

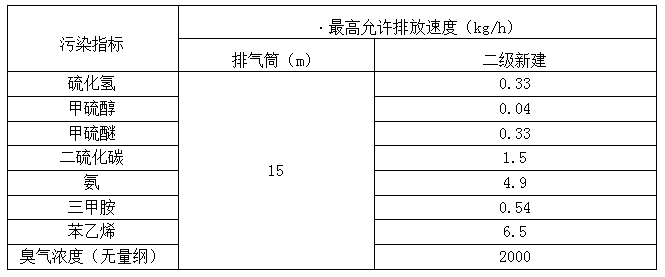

Table 1: "Integrated Emission Standard for Air Pollutants" (GB16297-1996)

Table 2: "rubber products industrial pollutant discharge standards" (GB27632-2011)

Table 3: "Odor Emission Standards" (GB14554-93)

10, the advantages:

1, can efficiently remove volatile organic compounds VOCs, sulfur dioxide, hydrogen sulfide, nitrogen oxides, non-methane total hydrocarbons, ammonia, benzene, toluene, xylene, formaldehyde, acetone, butanone, indole, nitro, sulfur Ether, mercaptans, phenols and other major pollutants, as well as a variety of odor, deodorization efficiency of up to 99% or more, deodorant effect greatly exceeded the national 1993 enactment of the stench pollutant discharge standards (GB14554-93) and 1996 Year "issued by the" Air Pollutant Comprehensive Emission Standard "(GB16297-1996).

2, low operating costs, low operating costs of treatment chemicals, long-term operation will not block the phenomenon does not rebound.

3, adaptable: adapt to a variety of high concentrations, the amount of the atmosphere, different industrial VOCs volatile organic compounds, inorganic substances and malodorous gases, purification efficiency, continuous 24-hour operation, safe and reliable operation.

4, a high degree of automation: the entire exhaust gas treatment system using PLC automatic control to achieve remote control and monitoring.

版权所有·北京天中方环保科技有限公司 京ICP备14001063号-2